Mechanical testing is an indispensable part of engineering and product manufacturing. These tests provide us with insights regarding the strength, durability, and performance of materials and components. Mechanical testing helps us to evaluate and measure the physical properties of the raw materials, like hardness, strength, elasticity, and ductility. During these tests, the materials are subjected to various forces, and then we evaluate the results we get. This way, we are able to get an understanding of the raw materials and how they will perform under various conditions. This will help us ensure the safety and Reliability of the product and the safety of the customer. It is essential to ensure that all the products that have been manufactured perform safely and efficiently in real-world conditions. Mechanical testing is done on each component and material used in products to ensure that these products meet the regulatory standards and safety requirements set by each country. In this guide, you can learn about Mechanical testing, types, standards, future trends, and how ELenergy’s Mechanical testing lab helps industries with cutting-edge solutions

What is Mechanical Testing?

Mechanical testing involves evaluating the mechanical properties of materials in controlled conditions. It assesses properties like strength, ductility, toughness, and fatigue resistance to ensure materials can withstand the conditions they will face throughout their lifespan. This process helps manufacturers and engineers understand how materials behave under stress and failure, providing essential data for quality control, certification, and failure analysis.

Historical Evolution of Mechanical Testing

Mechanical testing originated during the Industrial Revolution when blacksmiths and early engineers evaluated the strength of metals manually. Over the years, standardized techniques were established, and organizations such as ASTM and ISO introduced universal guidelines. Today, mechanical testing has evolved into a highly technical field that employs precise instruments, computer modeling, and advanced analytical methods.

Why Does Mechanical Testing Matter in Modern Industries?

As we know, Mechanical testing is a standard and also an important part of the designing and manufacturing process. Mechanical testing is required for each equipment to ensure the safety of the equipment and the people using them.

It is very important to know the mechanical properties of the raw materials before using them for the final product, as this will help you save costs that might occur due to equipment failure. Hence, Mechanical testing is an important aspect for determining the properties of the raw materials and making sure that it meets the benchmarking standards.

Key Benefits of Mechanical Testing

-

Ensures Safety and Reliability:

Mechanical testing verifies that products can endure stress and environmental conditions throughout their lifecycle, ensuring reliability and safety. -

Compliance with Regulatory Standards:

Mechanical tests provide documentation and data to meet national and international certifications, such as:

-

ASTM International Standards

-

ISO 9001 (Quality Management Systems)

-

ISO 17025 (Testing and Calibration Labs)

-

Improves Product Quality:

Testing helps improve product quality by revealing weaknesses and defects that could compromise performance and safety.

How Can Mechanical Testing Help You?

Mechanical testing consists of various tests, in which you can opt for a particular test based on your requirements. Never think of mechanical testing as an expense, as the initial investment in mechanical testing will save you far more, a mechanical test will provide you with the properties of the raw material, and it will help you to determine the quality and durability of your product. Mechanical testing is never an expense; it is an investment that will help you save costs and help you in manufacturing the best products and ensuring the safety of your customers. Here are some benefits of doing mechanical testing:

Ensuring Safety and Reliability

Mechanical testing will help you ensure that your products will be able to endure the stress and environmental conditions that they will be facing throughout their lifecycle. Testing the products and materials will help us verify their reliability and safety. Mechanical testing has been done on everything from construction materials to automotive parts, aerospace components, and electrical meters.

Meeting regulatory standards

Many industries, such as electronics, construction, and automotive, have set national and international standards that help to ensure the necessary safety and compliance of the product.

Mechanical testing will provide you with the documentation and data to meet national and international certifications. Common standards include

Improving Product Quality and Performance

Mechanical testing helps manufacturers to ensure that their products are of the highest quality standards. Mechanical testing allows manufacturers to assess the tensile strength, hardness, and vibration resistance. With this information, manufacturers can improve their products’ performance and reduce the risk of failures in the field. This is especially important in the medical and energy industries, where product failure can have serious consequences.

In conclusion, these are the benefits that are gained by mechanical testing your products :

- Determine the properties of the raw materials under various scenarios, such as bending, compression, tension, or twisting.

- Identify the defects and weaknesses of the material that might affect the working of the product and ensure the safety of the product.

- Mechanical testing will help you to verify that your equipment meets the minimum benchmark industrial standard of that particular application.

- By identifying the mechanical properties of various raw materials, you will be able to choose the best cost-effective and suitable material for your product.

- Mechanical testing ensures the safety and reliability of a manufactured product, which is important to have a reputation in the market, and also to achieve customer satisfaction

Types of Mechanical Testing Methods

According to Wikipedia, Mechanical testing consists of various tests and is divided broadly into two types

- The first type of test is used to determine the material’s mechanical properties, regardless of its geometry.

- The second type of test is used to determine the structure’s response to an action. For example, composite beams, aircraft structures, etc., are tested to destruction.

The mechanical testing industry is vast and varied, offering numerous specializations and tests. Every test type serves its own specific purpose; choosing the appropriate test for any given application can be crucial – for instance, projects located in high-pressure environments require hydraulic or pneumatic testing as well as vibration and thermal resistance analysis.

Testing occurs throughout the manufacturing process, from product development and design validation, where prototypes are put through rigorous performance tests to see how they will fare in real-life conditions, to production quality control, where completed products are checked against all necessary specifications and performance criteria.

Mechanical testing exposes samples of materials to different loads, such as compressive, tensile or impact loads, to assess how well they perform under various loading conditions. Test results are then compared with benchmark values to provide insight into their performance – this information can then be used to create more efficient designs and materials that last longer and deliver on performance promises in real-world applications.

There are various types of mechanical testing, each designed to determine specific properties of a material. For example, the Charpy V-notch and Izod tests measure material toughness. In contrast, the Vickers hardness test specifically assesses hardness. Unlike these, some tests, such as the tensile test, provide information on multiple mechanical properties at once; the tensile test not only measures tensile strength, but also yield strength, ductility or brittleness, and the modulus of elasticity. These results are obtained from the stress-strain curve generated during testing, which continues until the material fractures.

Mechanical testing is an integral component of product development and manufacturing industries as a whole. By evaluating the mechanical properties of different samples, engineers can avoid costly mistakes that could cause product failures or damage to machinery and equipment. When choosing testing methods, always select ones tailored specifically for application or service conditions so that their results reflect real-world performance accurately..

Hardness testing

This test is used to determine the hardness of the material or to determine the resistance to mechanical deformation from various methods. The hardness test is used primarily to gather information to determine if the material is suitable and to find the mechanical properties, such as strength and wear resistance, of the material. The hardness testing is used as an industry standard across industries like automotive, construction, aerospace, and manufacturing, where it is important to determine how the material will behave under stress.

Depending on the material type and thickness, various methods are widely used.

- Brinell hardness test

- Knoop hardness test

- Meyer hardness test

- Rockwell hardness test

- Vickers hardness test

- Janka hardness test

- shore durometer hardness

- Barcol hardness test

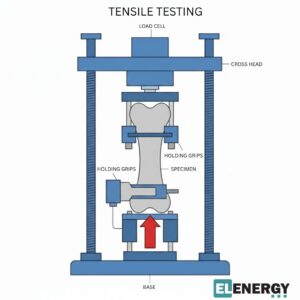

Tensile Testing

Tensile testing helps us determine the strength of a material under tension, ensuring the material meets minimum requirements for strength and ductility. Tensile testing measures a material’s ability to withstand stretching by stretching it to its breaking point, revealing properties like ultimate tensile strength, yield strength, and elongation. In addition to tensile strength, tensile testing also provides a stress-strain curve, yield stress, tensile stress, Young’s Modulus, and percentage elongation to failure of the material. Used in metals, polymers, and composites, tensile testing helps engineers design safer and more efficient products.

Impact Testing

Impact testing determines a material’s toughness or the force a mechanical part can endure before it breaks. It usually involves a swinging pendulum striking the material. Some of the most common tests for impact testing include ASTM standardized tests like Izod Testing and Charpy Testing.

Why Impact Testing is Critical

Impact testing helps reveal how certain materials will behave when faced with sudden shocks or under extreme conditions. This test is crucial in the defense and aerospace industries.

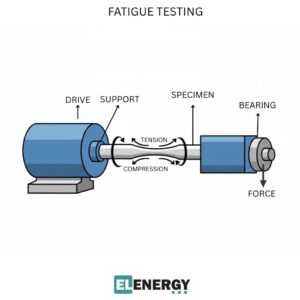

Fatigue Testing

Fatigue testing assesses a material’s ability to withstand repeated loading and unloading cycles, ultimately predicting how long it will last under these conditions before failure. The Stress-Life (S-N) approach is typically used for high-cycle fatigue, where materials experience many cycles at relatively low stresses.

Fatigue testing allows you to determine the fatigue strength of the material under question, offering insights into the number of load cycles the material can go through before experiencing failure and allowing you to schedule maintenance. You can compare the fatigue strength curve of the material to your design criteria to ensure the material and part are fit to serve your purpose. However, it is advisable to fatigue test the finished part instead of the raw material, as its geometry often alters its mechanical properties. Some popular standardized tests for fatigue testing include Fatigue Crack Growth Testing, Strain-controlled Smooth Specimen Testing, and Load-controlled Smooth Specimen Testing.

Stress-Life (S-N) Approach

Fatigue testing is used to assess a material’s ability to withstand repeated loading and unloading cycles. The stress-life (S-N) curve helps predict the number of cycles a material can endure before failure.

High-Cycle vs. Low-Cycle Fatigue

High-cycle and low-cycle fatigue tests play an important role in the automotive, aerospace, and structural engineering sectors. In this test, the materials experience a load cycle at different stress levels. In high-cycle fatigue, the materials experience many cycles at a low stress level, while in low-cycle fatigue, the materials experience fewer cycles but at a higher stress level.

Creep Testing

Creep testing allows you to determine the effects of long-term stress on the material or parts that deform over time when subjected to a constant load at high temperatures relative to the boiling point. The test involves applying constant stress at a constant temperature to the specimen to record the strain versus time graph. The primary purpose of this analysis is to evaluate a material’s long-term strength and identify its potential failure points. Creep testing is all about seeing how materials gradually change shape when they’re under constant stress for a long time, especially when things get hot. It helps us figure out how tough these materials really are and how they’ll hold up in real-life situations. Materials like turbine blades or high-performance alloys are often subjected to creep testing.

Applications in High-Temperature Materials

Creep is critical for industries that deal with materials exposed to extreme heat, such as the energy sector and nuclear reactors. The data helps engineers design longer-lasting, more durable components.

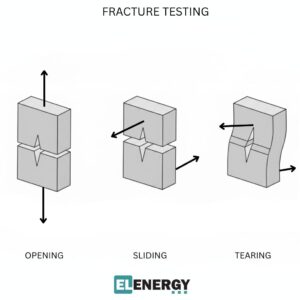

Fracture Toughness Testing

Fracture toughness testing helps us to figure out how well a material resists cracks when it’s under pressure. This test gives us a valuable insights of how a material can deal with imperfections, like cracks, and helps us understand how long a part can last before it risks failing completely.By understanding these factors, you can effectively plan maintenance and repair schedules for various mechanical components. The most widely used tests for assessing fracture toughness include Linear-elastic, K–R Curve, and Elastic-Plastic tests.

Fracture toughness testing looks at how well a material can handle cracks when put under stress. It’s really important for materials used in high-pressure situations, aerospace, marine environments, and automotive crash testing

Relevance in Aerospace and Automotive

Fracture toughness is really important for safety-sensitive parts like aeroplane wings, engine components, and car frames. Testing these materials helps make sure they can handle any potential issues that might come up.

Need testing for your electrical components? Explore our specialized testing services for electrical meters and more at EL Energy Lab

Corrosion Resistance

Corrosion resistance testing gives us insights into a material’s susceptibility to rust, chemical damage, and the typical wear and tear it may experience. Typically, you can assess corrosion resistance by placing small samples of the materials in a specific environment over a relatively short period, then analyzing the severity and type of corrosion that occurs. This way, you are able to choose the most suitable material for your needs and maximize the part’s lifespan.

Non-destructive Testing

Non-destructive testing is a way to check the mechanical properties of a material without causing any damage to the material or the part. There are several methods to do this, like Acoustic Emission Testing, Electromagnetic Testing, Ground-Penetrating Radar, and Laser Testing. Since these techniques are non-destructive, they don’t harm the material or part being examined, making them versatile and able to be used across different industries.

Standards and Certifications in Mechanical Testing

ASTM Standards

The American Society for Testing and Materials (ASTM) is an important global standards in materials testing, which helps industries around the world trust the quality and consistency of what they’re working with. To give an example is ASTM E8, which outlines how to do tensile testing on metals. This process is key to determining the strength and durability of the materials we use daily. When companies stick to these standards, they can confidently produce reliable products that meet safety and performance expectations.

ISO Standards

International Organization for Standardization (ISO) standards, such as ISO 6892 outlines standardized procedures for tensile testing and ISO 13445 specifies guidelines for testing pressure vessels. These standards provide comprehensive and globally recognized methods to check how the materials will perform and their safety. These ISO standards ensure that the companies’ testing processes meet high international industry standards, thereby enhancing product reliability and building trust among consumers and regulatory bodies alike.

Industry-Specific Standards

In addition to general standards, Industries usually have their own specific rules on top of the general ones. For example, Aerospace AS9100 dictates strict tests for materials used in aircraft to make sure everything is safe when building planes, ensuring safety in aircraft construction.

Learn more about our services at EL Energy Lab.

Applications of Mechanical Testing Across Industries

Mechanical testing plays a major role in product development and assuring quality across several industries. Below are some of the industries that use mechanical testing in their product development:

Aerospace

In the aerospace industry, mechanical testing is used make sure that the materials used in planes, satellites, and spacecraft are safe and reliable, ensuring their safety and reliability. Key mechanical tests like fatigue testing, fracture toughness testing, and impact testing are used to ensure materials are able to handle the extreme stress and environmental conditions.

Automotive

The automotive industry depends on mechanical testing in order to evaluate the performance and safety of their key components like engines, brakes, and chassis. They use methods such as vibration testing and shock testing to understand how these parts can handle various stresses, like vibrations, impacts, and temperature fluctuations during operation.

Electronics

In electronics, testing ensures that components like printed circuit boards (PCBs), semiconductors, and wires meet the necessary industry standards for performance and safety. Various testing methods, such as vibration testing, temperature cycling, and shock testing, are used to ensure that products function reliably in the field.

Energy and Power

The energy sector depends on mechanical testing to ensure materials and components will perform well under extreme conditions. For example, creep testing is used to evaluate how well materials perform in high-temperature environments, such as those found in turbines, nuclear reactors, and power lines.

EL Energy Lab: Your Trusted Partner in Mechanical Testing

At EL Energy Lab, we provide highly accurate mechanical testing services designed to support industries worldwide. Our state-of-the-art facilities and industry certifications allow us to offer comprehensive testing services that meet both national and international standards.

Why Choose EL Energy Lab for Your Mechanical Testing Needs?

We are committed to providing high-quality mechanical testing services to industries worldwide. As a NABL-accredited lab, we adhere to international testing standards, ensuring accurate and reliable results. Our experienced team uses the latest technology and testing protocols to meet the specific needs of our clients.

Our Mechanical Testing Services Include:

- Tensile Testing

- Impact Testing

- Hardness Testing

- Vibration and Shock Testing

- Environmental Testing (Dry Heat, Cold, Damp Heat)

- Glow wire test

Whether you need to certify materials, verify product safety, or conduct failure analysis, our lab provides the critical data to make informed engineering decisions.

Ready to test your materials with precision? Contact EL Energy Lab’s Mechanical Testing Lab for expert testing services

How Mechanical Testing Supports Innovation

Mechanical testing isn’t just about making sure products are safe and compliant. It’s about fostering innovation in materials science and engineering. Testing helps develop better materials, supports research, and enables sustainable engineering practices.

Driving Material Development

Through mechanical testing, manufacturers are able to develop new materials with enhanced properties, such as:

Increased tensile strength

Corrosion resistance

Thermal stability

These improved properties create more durable, reliable materials that meet the needs of industries like aerospace, automotive, and construction.

Supporting Research and Academia

Mechanical testing plays a huge role in academic research. Researchers and universities use it to:

Test new theories.

Create innovative solutions.

Push the boundaries of engineering.

This collaboration between academia and industry sparks breakthroughs that shape the future of materials science and engineering.

Enabling Sustainable Engineering

As industries work toward more sustainable solutions, mechanical testing helps develop eco-friendly materials that last longer and are more cost-effective. These materials:

Use fewer resources.

Are more durable.

Have a smaller environmental impact.

Mechanical testing makes sure these materials perform well while supporting a greener future.

Common Challenges in Mechanical Testing

Mechanical testing offers tons of valuable insights, but it does come with a few challenges. Here’s what you need to watch out for:

1. Sample Preparation Issues

Making sure your samples are prepared correctly is essential. If the specimen dimensions, surface finish, or alignment are off, it can throw off the results.

2. Accuracy and Repeatability

For reliable results, accuracy and consistency are key. Small changes in environmental conditions or equipment calibration can lead to varying outcomes.

3. Equipment Calibration

For high-precision tests, like fracture toughness or fatigue testing, equipment needs regular calibration. This ensures you get reliable, accurate results every time.

Future Trends in Mechanical Testing

As technology continues to evolve, so does mechanical testing. Here are a few exciting trends shaping its future:

1. Automation and Robotics

Mechanical testing labs are becoming more automated, making testing faster and more efficient. Robots handle repetitive tasks, which reduces human error and boosts throughput.

2. AI and Data Analytics in Material Testing

Artificial intelligence is transforming how we analyze test results. AI helps:

Detect patterns in large datasets.

Predict material behavior before it happens.

Prevent failures by optimizing materials for specific uses.

3. Sustainable Testing Practices

With the growing focus on eco-friendly solutions, mechanical testing is becoming more sustainable. This includes:

Reducing energy consumption.

Using more efficient testing methods.

Cutting down on waste generated during tests.

Final Thoughts

Mechanical testing is more than just a tool for ensuring safety and compliance. It’s a key player in driving material innovation, supporting research, and enabling sustainable engineering practices. Whether you’re developing new materials, pushing the limits of engineering, or ensuring your products are safe and reliable, mechanical testing helps make it all possible.

For expert guidance and precise testing, reach out to EL Energy Lab, where we offer reliable and comprehensive mechanical testing solutions tailored to your needs.

FAQ

Mechanical testing involves evaluating materials' mechanical properties, such as strength, ductility, and toughness, to ensure they perform as required in real-world applications.

It helps manufacturers select the best materials, verify product durability, and ensure compliance with safety standards.

The key tests include:

Tensile testing: Measures strength under tension.

Hardness testing: Assesses a material's resistance to deformation.

Impact testing: Tests how materials respond to sudden forces.

Fatigue testing: Examines durability under cyclic loading.

These tests measure a material's ability to withstand forces and stresses over time

The duration varies depending on the test:

Simple tests like tensile testing may take a few hours, while tests like fatigue testing may require several days.

Mechanical testing ensures that materials will perform safely and reliably under the stresses they will face during use.

- It helps to prevent product failures

Perform reliably under real-world conditions.

Comply with industry regulations.

Improve product durability and reduce the risk of failure.

The right testing method depends on:

The material you're testing.

The application of the product.

The specific performance requirements.

At EL Energy Lab, we have experts who can guide you in choosing the best method for your needs to ensure you get accurate and reliable results.

Thanks for giving pictorial reference for each test , it helped to understand it better

This post was exactly what I needed to better understand mechanical testing in manufacturing

I didn’t know mechanical testing played such a huge role in quality control

I always knew testing was important, but this really highlighted just how vital it is in product development

Really interesting read

Thanks for making this topic so easy to understand

Simple but very informative. Thanks

I love how you broke this down. Very easy to understand

Such a well-written post. You’ve definitely got me thinking

This post is a perfect starting point for anyone new to mechanical testing. I learned a lot

This was a great overview of mechanical testing. The real-world examples really brought it all together.

I love how you broke down the different tests. It makes it so much easier to follow.

This post really helped me understand the different types of mechanical testing. Great explanation