Electromagnetic compatibility (EMC) testing is often the unsung hero behind the reliable operation of modern electronic devices. This process ensures that your smartphone, medical equipment, car control system, or any electronic gadget does its job without causing trouble for other equipment nearby and can function even when surrounded by electromagnetic signals. Let’s take a closer look together at how EMC testing works, why it’s needed, and how you can approach it for your own products or interests, sharing actionable advice and friendly explanations along the way.

What is Electromagnetic Compatibility (EMC) Testing?

EMC, short for electromagnetic compatibility, means a device is able to work well in spaces full of electromagnetic signals, without messing with other electronics or becoming unreliable due to interference. In plain terms, EMC testing checks that your device can share airwaves and electrical lines with its neighbours, while still performing as intended. This simple need drives a wide array of EMC standards, regulations, and lab-based tests every manufacturer must address before launching new tech.

Why EMC Testing Matters

Think about living in a sea of electronics, phones, routers, smart thermostats, cars, even medical gear like pacemakers. Each device emits electromagnetic energy (sometimes intentionally, like a Wi-Fi router, sometimes not, like a blender). EMC testing is vital to ensure one device doesn’t accidentally make another fail, avoiding anything from annoying glitches to downright dangerous malfunctions.

EMC testing is essential for:

- Regulatory compliance: Most countries require products to be certified before they’re sold.

- User safety: Prevents interference that may endanger lives.

- Reliable operation: Prevents random failures due to outside electromagnetic disturbances.

- Global market access: Certification is often mandatory for international sales.

- Customer satisfaction: Fewer returns and service calls, better reputation.

The Key Components of EMC Testing

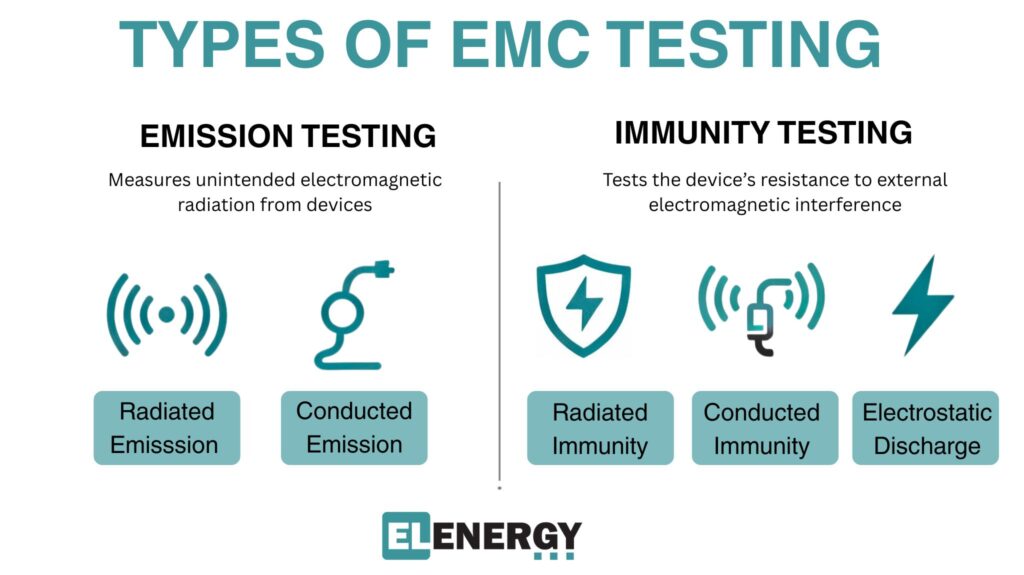

EMC testing is made up of two major types:

- Emissions Testing: Measures the amount of electromagnetic energy your device gives off. This ensures nothing goes over recommended levels for airwaves or power cables, which could mess with other equipment.

- Immunity Testing: Assesses how well your device holds up against interference from other electronics or environmental noise.

Typical EMC Test Types

- Radiated Emissions: Checks the radio signals your device puts into the air.

- Conducted Emissions: Looks at signals and noise traveling through wires and cables.

- Radiated Immunity: Tests if your device can continue to function in strong electromagnetic fields.

- Conducted Immunity: Simulates disturbances fed directly into power or signal lines.

- Electrostatic Discharge (ESD): Mimics what happens when people or objects touch your device and transfer a static electric shock.

EMC Standards and Regulatory Frameworks

Regulatory bodies across the world define standards that spell out how much electromagnetic emissions are permitted and what tests are needed. For instance:

- United States: FCC Part 15

- Europe: CE Marking per the EMC Directive

- Canada: Industry Canada rules

- International: CISPR, IEC, ISO standards

Product categories may have additional specialised standards, such as MIL-STD-461 for defence, RTCA–DO-160 for aerospace, or medical device-specific guidelines. It’s always important to align your testing or certification strategy to your target market’s regulations.

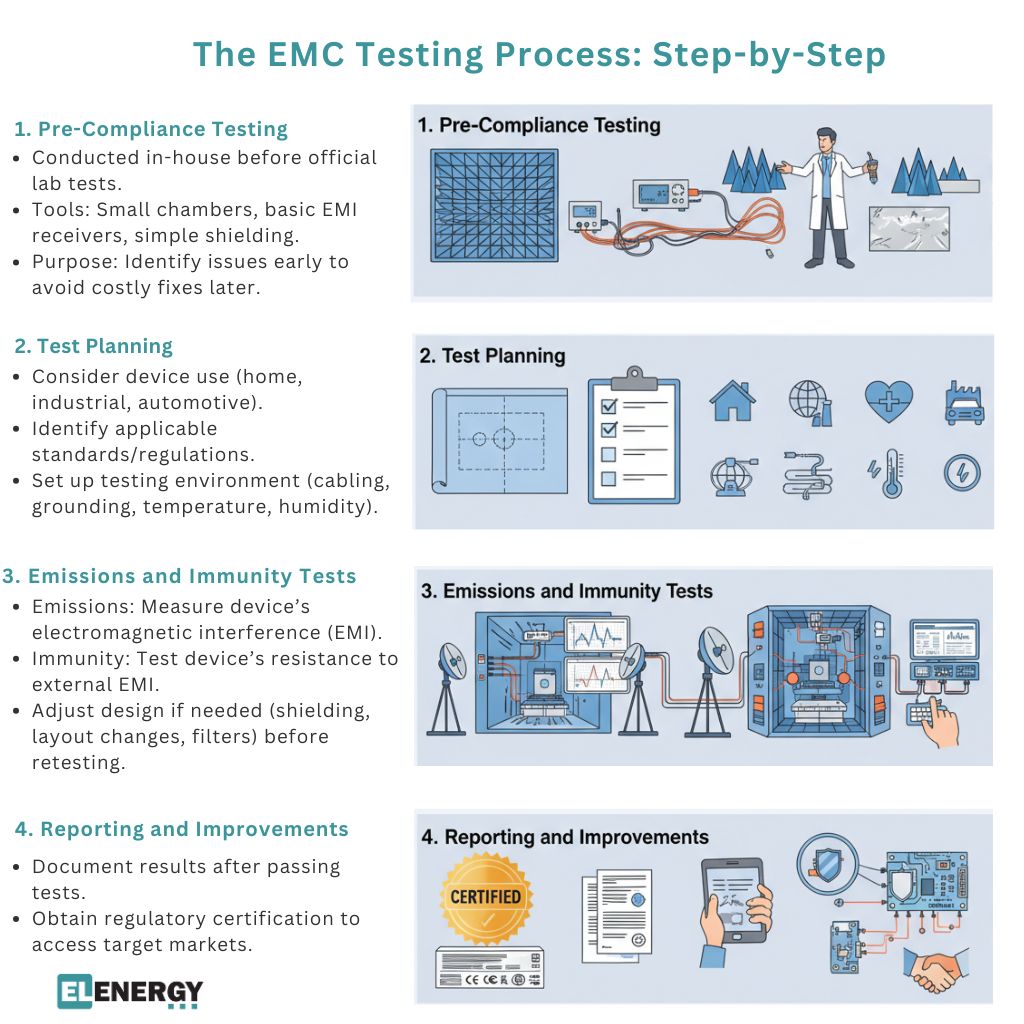

The EMC Testing Process: Step-by-Step

Let’s break down how most manufacturers or design teams approach EMC testing:

1. Pre-Compliance Testing

Before heading to an official lab for certification, companies often run “pre-compliance” tests using in-house setups. This cost-effective step helps catch obvious issues early, reducing project risks and avoiding costly retests. Common pre-compliance tools include small anechoic chambers, basic EMI receivers, and simple shielding setups.

2. Test Planning

A successful EMC testing plan considers:

- Intended use of the product (home, industry, medical, automotive)

- Applicable standards and regulations

- Physical setup: location, cabling, grounding, mounting

- Test samples and documentation

- Test environment: temperature, humidity, supply voltage

3. Emissions and Immunity Tests

Devices are then placed into shielded test chambers or labs, connected to antennas and monitoring equipment, and systematically checked for emissions and immunity at defined frequencies. Sophisticated labs use automated test scripts, varied interference sources, and thorough logging.

4. Reporting and Improvements

Test results are documented and analyzed; devices failing any limits often undergo design tweaks (component shielding, layout changes, filter addition) before going through retesting.

5. Certification

Passing results and proper documentation form the basis for regulatory certification, unlocking access to chosen markets.

Real-World Applications and Product Categories

EMC testing isn’t limited to high-tech gadgets; it applies broadly:

- Consumer electronics (phones, laptops, TVs)

- Medical devices (defibrillators, pacemakers, imaging systems)

- Automotive systems (engine controls, sensors, infotainment gear)

- Industrial equipment (robots, control panels, drives)

- Communication networks and wireless modules

- Aerospace components

In all these fields, EMC matters, even the smallest module can create serious problems if it’s not designed to operate harmoniously within an electromagnetic “ecosystem”.

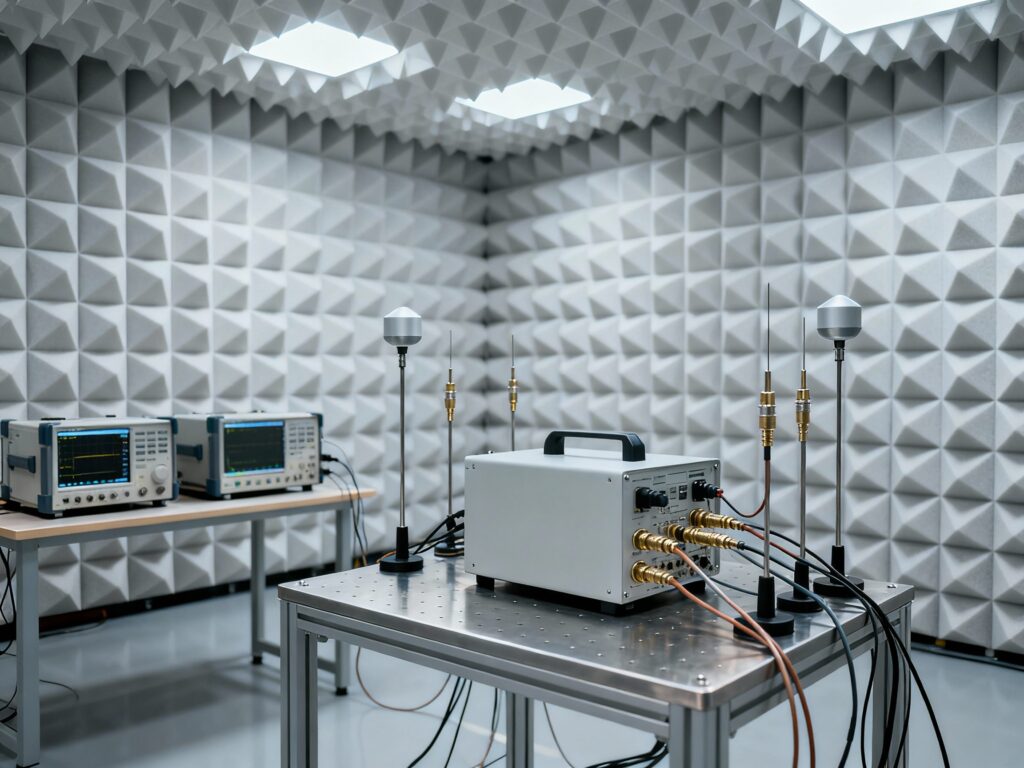

EMC Testing Equipment

Modern EMC labs are equipped with specialized gear for accurate measurements and challenging real-world environments, including:

- Anechoic chambers (block outside signals for clean testing)

- EMI receivers and spectrum analyzers (detect weak signals)

- Calibrated antennas (capture emissions)

- Electrostatic discharge simulators

- Injection probes for conducted immunity

- Data recording and automation systems.

Professional reports from accredited labs can also speed up product launch timelines.

Best Practices for Success

To help ensure both compliance and product reliability, consider these friendly tips:

- Start testing early: Pre-compliance tests save money and stress.

- Document thoroughly: Keep records of everything for easy retests.

- Choose the right lab: Accredited labs have the right equipment and expertise.

- Understand standards: Align with region-specific guidelines from the start.

- Design for EMC: Budget for shielding, grounding, and layout strategies during product development.

- Build for future updates: Products may need retesting after design changes or in new markets.

Challenges and Solutions

EMC failures can be frustrating, but most stem from simple causes:

- Poor grounding and cable routing

- Inadequate shielding or filters

- Unshielded connectors or displays

- Unexpected interactions in software/firmware

Quick fixes often involve redesigning printed circuit boards (PCBs), adding ferrite beads, improving chassis shielding, and rerouting cables. Engage with EMC experts or labs for advice as soon as issues appear.

Final Thoughts

Electromagnetic compatibility testing is a critical part of modern electronics development. It keeps devices running smoothly, protects users and public safety, and ensures products reach their intended markets. Whether you’re developing smart gadgets, industrial tools, or medical technology, planning for EMC testing from the start will save time, money, and reputation.

Following best practices in EMC testing and optimising your content for search engines can position you as a trusted resource in your industry. Begin your journey with a focus on clear information and active engagement, so users and search engines alike see the value you’ve brought forward.

If you have more specific questions or need advice on launching your next product, don’t hesitate to seek out professional EMC consultants or labs. They’ll help you solve problems faster and get closer to that stamp of market approval.

Small-scale tests can be done in-house for pre-compliance, but final certification usually needs an accredited lab with specialized equipment and expertise.

Start by identifying markets where you plan to sell, then review national and international regulations that fit your device category.

Most failures happen due to unexpected emissions or insufficient immunity. Early pre-compliance testing helps uncover and solve common problems quickly.

Thanks for the great read, Very insightful points.